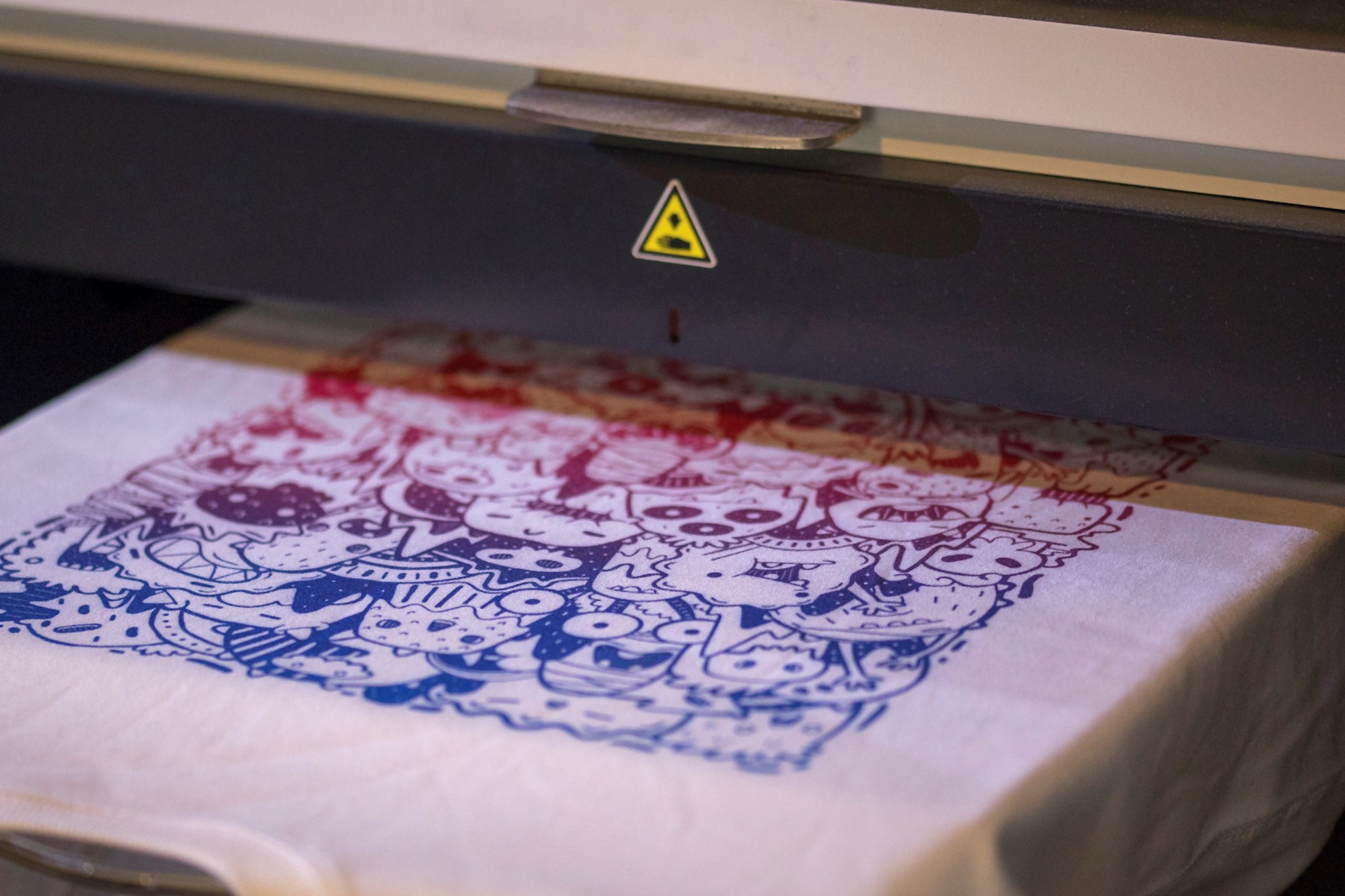

Direct to Garment

Notice - New location in Wolvertem

We are now located at a new address:

De Biest 23, 1861 Wolvertem

(about 1 km closer!)

Please take this into account when collecting your orders.

Contact via 02 460 85 35, info@tiptopprint.be or via our contact page.